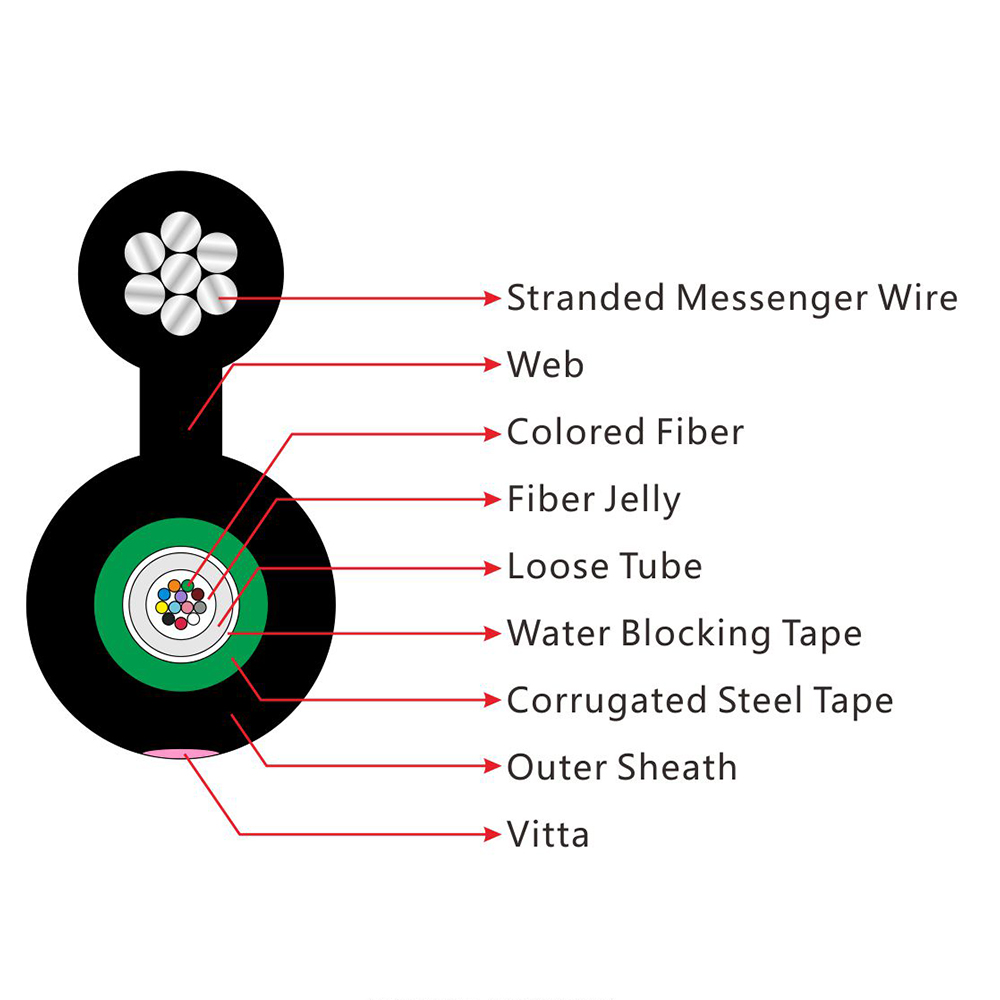

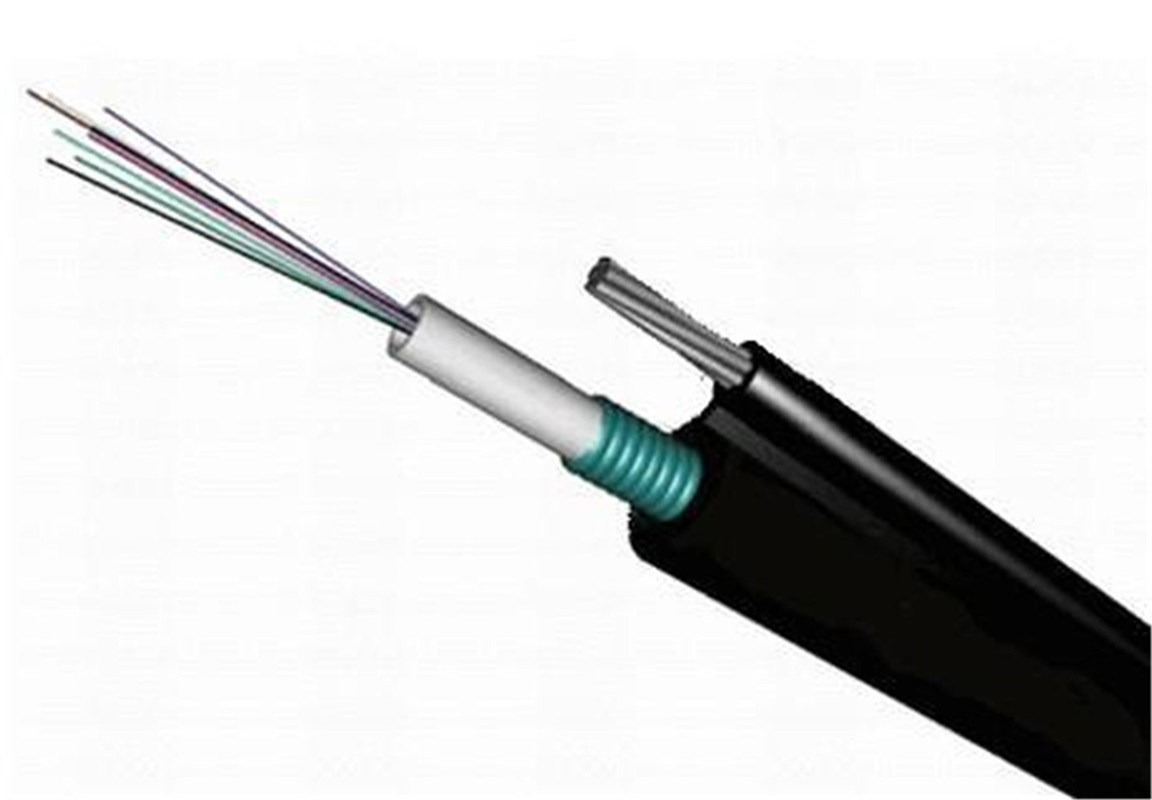

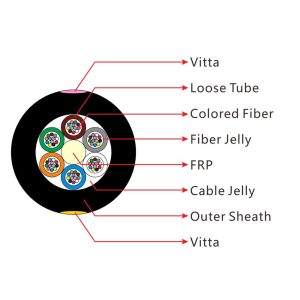

The fibers, 250μm,are positioned in a loose tube made of a high modulus plastic, the tubes are filled with a water-resistant filling compound. The two sides PSP are longitudinally applied over the outer loose tube. Steel wires and loose tubes filled with water proof compound to ensure compact and longitudinally water blocking ,this part of cable accompanied with the stranded wires as the supporting part are completed with a polyethylene(PE) sheath to be figure 8 structure.

| Cable Type | Fiber Count | Cable Diameter mm |

Cable Weight kg/km | Supporting Wire Spec | Connection Diameter | Tensile Strength Long/Short Term N | Crush Resistance Long/Short Term N/100mm | Bending Radius Static/Dynamic mm |

| GYXTC8S | 2~12 | 7.65×14.5 | 118 | Φ1.0mm*7 Stranded wires |

Height×Width 3.0×2.5 mm |

1000/2500 | 300/1000 | 80/160 |

| GYXTC8S | 14~24 | 8.2×15.1 | 129 | Φ1.0mm*7 Stranded wires |

Height×Width 3.0×2.5 mm |

600/1500 | 300/1000 | 90/180 |

Storage/Operating Temperature : -40℃ to + 60℃